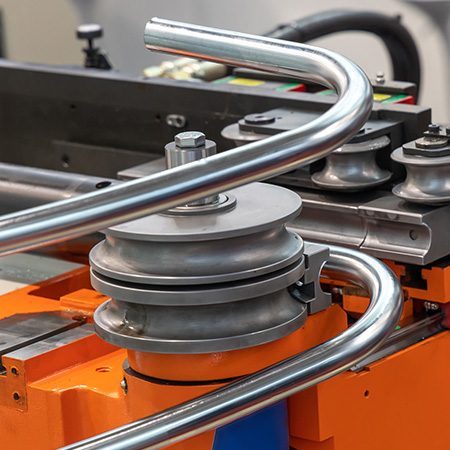

What is Mandrel Bending?

Mandrel bending is a precise technique within rotary draw bending where a solid mandrel shaft, equipped with up to five segmented, donut-shaped balls slightly smaller than the inner diameter (ID) of the pipe or tube being bent, is introduced into the pipe or tube during the bending process. The purpose of the mandrel is to provide internal support while bending, preventing issues such as distortion, collapsing, rippling, and flattening. This method allows technicians to maintain better control over the ovality or roundness of the pipe or tube.

This bending method is particularly advantageous for intricate tasks involving tight and large radius bends, multiple radii, high precision, and repeatable results with minimal deformation. Apart from enhancing project quality, mandrel bending offers cost savings of over 50% compared to cutting and welding processes, as it reduces fabrication time, materials, and expenses related to weld inspection.

Common Misconceptions and Facts about Mandrel Bending

There are several misconceptions surrounding mandrel bending stainless steel, which can obscure its actual benefits. Here are some myths and corresponding facts:

Myth: Bending is weaker than welding.

Fact: Both bending and casting are common methods for pipe fittings, and there is no inherent weakness in one over the other. In some cases, materials can actually become stronger through bending due to work-hardening.

Myth: Stainless steel bends require post-bend heat treatment.

Fact: Austenitic stainless steel, categorized under base metal P-No 8, can be cold-bent according to ASME Code without necessitating post-bend heat treatment.

Myth: Bends lack consistent diameter like pre-made elbows.

Fact: Mandrel bends adhere to ASME specifications for wall thickness and ovality, ensuring consistency. With internal mandrel support, technicians achieve accurate and repeatable bends.

Myth: Accurate angles can’t be achieved in stainless pipe and tube bends.

Fact: Bending stainless steel offers greater accuracy than welding due to the avoidance of weld distortion and fit-up issues. Mandrel tool-based bending prevents damage during the process.

Check out our vast collection of 304 Stainless Steel Mandrel Bends!

Why Choose Haze Performance?

Engineered for quality, Haze is the ultimate hub for providing aftermarket parts for car enthusiasts to upgrade their vehicles.

Haze specializes in producing top-grade stainless steel exhaust systems with all the necessary features to create a better driving experience. Work on your exhaust system with a range of high-quality products from a team of automotive and racing enthusiasts.

We’re committed to sourcing only premium-grade materials that guarantee superior results with every exhaust system upgrade we make — because there’s no room for compromise regarding performance. Discover the Haze difference now!