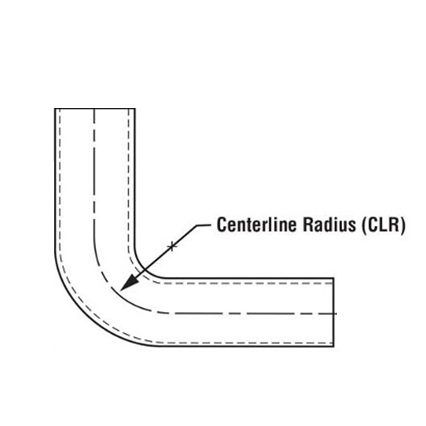

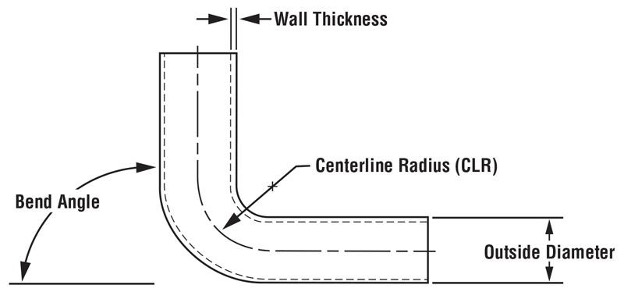

What is the Centerline Radius? (CLR)

Frequently, we encounter inquiries seeking clarification about the concept of Centerline Radius, commonly abbreviated as CLR. The Centerline Radius (CLR) of a bend corresponds to the measurement from the center of the bending die to the axis (or centerline) of the tube or pipe being bent.

Understanding the Centerline Radius (CLR) of a Bend

When engaged in the fabrication of components like headers, downpipes, or exhaust systems, a critical dimension to focus on is the Centerline Radius of the bend. The appropriate CLR is pivotal, as using a radius that is either excessively tight or too loose for the given application can lead to complications. Such issues might result in improper fitment of the fabricated item within the application or significant misalignment of the inlet or outlet. It’s not uncommon for a set of headers to necessitate a combination of standard and tight radius bends, or for a custom downpipe to require the tightest possible bend radius to clear specific parts of the vehicle. Recognizing the necessary CLR plays a crucial role in procuring the correct fabrication components tailored to the specific demands of the task at hand.

Why Choose Haze Performance?

Engineered for quality, Haze is the ultimate hub for providing aftermarket parts for car enthusiasts to upgrade their vehicles.

Haze specializes in producing top-grade stainless steel exhaust systems with all the necessary features to create a better driving experience. Work on your exhaust system with a range of high-quality products from a team of automotive and racing enthusiasts.

We’re committed to sourcing only premium-grade materials that guarantee superior results with every exhaust system upgrade we make — because there’s no room for compromise regarding performance. Discover the Haze difference now!